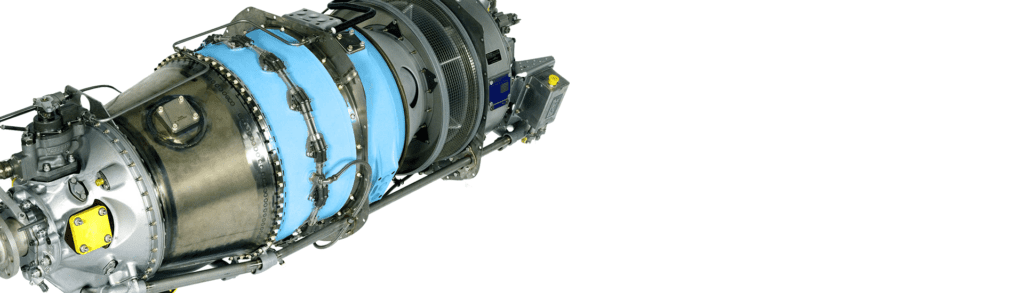

The Role of the Low Compressor Hub in a JT15D Engine and Maintenance Tips

Discover the critical role of the low compressor hub in the JT15D engine and learn essential maintenance tips to enhance performance and reliability. From regular inspections to proper cleaning and balancing checks, find expert advice to extend its lifespan and preserve its value. Trust BFG Aerospace for high-quality engine components and support.

Why the JT15D Series Remains Popular: Versatility and Reliability

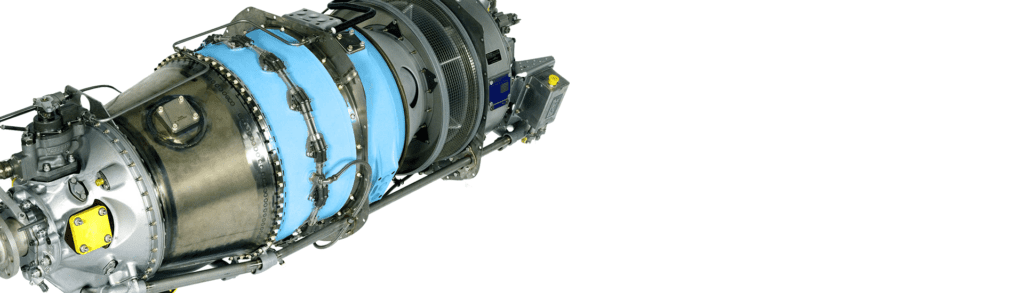

Why the JT15D Series Remains Popular: Versatility and Reliability The Pratt & Whitney Canada JT15D series stands out for its proven performance, low maintenance costs, and versatility across aircraft types like business jets and trainers. With millions of flight hours and a robust support network, it remains a trusted choice for operators worldwide. Learn why the JT15D continues to set the benchmark for reliability and efficiency.

An In-Depth Look at the JT15D Series: Evolution and Performance

Discover the evolution of the Pratt & Whitney JT15D engine series in our in-depth guide. Learn about the history, technological advancements, and engineering improvements that have kept the JT15D relevant in business aviation for decades. From fuel efficiency to noise reduction, explore what makes the JT15D a trusted engine for aircraft like the Cessna Citation. Find maintenance tips, aftermarket support, and more with BFG Aerospace.

Comprehensive Maintenance Checklist for PT6A Engines

Maintaining the reliability and performance of PT6A series engines requires a thorough and consistent maintenance approach. In this article, BFG Aerospace outlines a detailed checklist designed to assist operators and maintenance professionals in ensuring optimal engine functionality. Key focus areas include regular inspections, adherence to manufacturer-recommended maintenance intervals, and the significance of environmental considerations on engine health. By following this comprehensive guide, stakeholders can mitigate the risk of in-flight failures and extend the service life of their PT6A engines.

The Impact of Environmental Conditions on PT6A Engine Maintenance

The Pratt & Whitney PT6A engine is renowned for its versatility and reliability across diverse operating environments. However, varying environmental conditions—such as extreme temperatures, humidity, dust, and altitude—can significantly influence maintenance requirements. This article delves into how these factors affect engine performance and outlines strategies for optimizing maintenance schedules to ensure longevity and reliability.

Understanding PT6A Engine Overhaul: When and Why

The PT6A engine is renowned for its reliability and performance, but like all mechanical systems, it requires periodic overhauls to maintain optimal functionality. This article delves into the critical aspects of the PT6A engine overhaul process, helping operators recognize the signs indicating the need for an overhaul and understand the benefits of timely maintenance. By staying proactive with engine maintenance, operators can ensure enhanced reliability, performance, and safety, ultimately leading to more efficient and cost-effective operations.

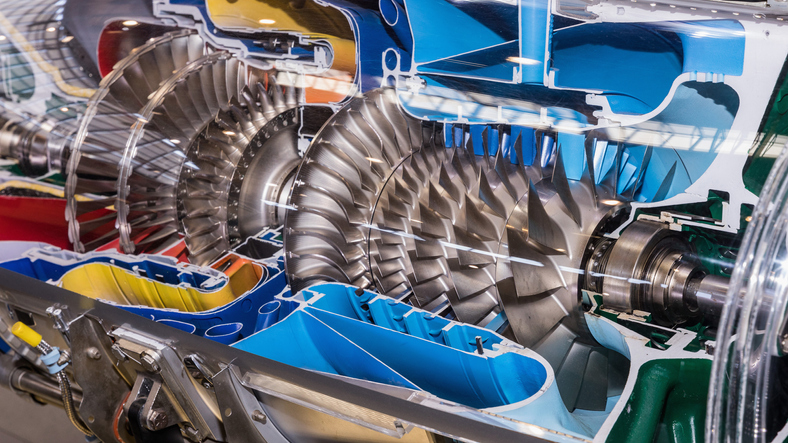

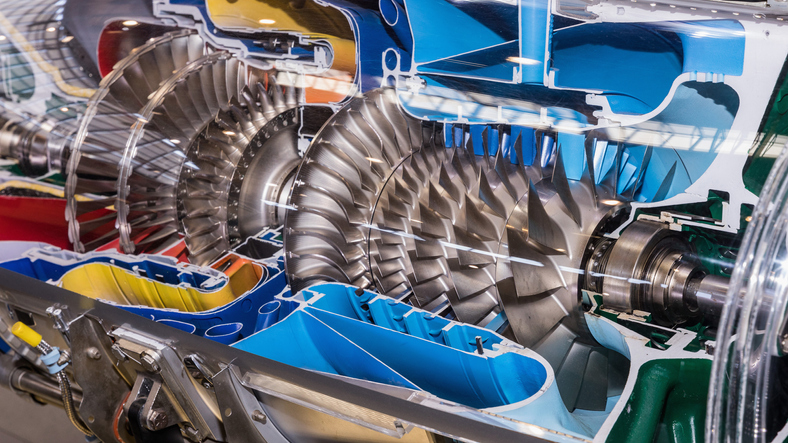

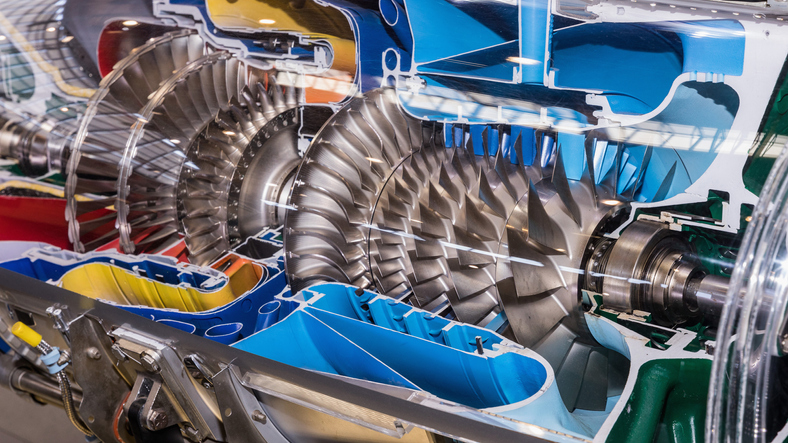

Unveiling the Crucial Role of CT Disk in PT6A-28 Engine: A Comprehensive Guide

In this article, we delve into the significance of the CT disk in the PT6A-28 engine, its functionality, and why understanding its role is crucial for aviation enthusiasts and industry professionals alike.

Versatilty of the PT6A Engines

Unveiling the Versatility of PT6A Engines: Powering a Multitude of Aircraft and Missions Across Industries

Exploring the Reliability and Safety Features of PT6A Engines

PT6A – Powering the Skies Safely and Efficiently:

Reliability and safety features of PT6A engines, their track record for durability, ease of maintenance, and operational flexibility.

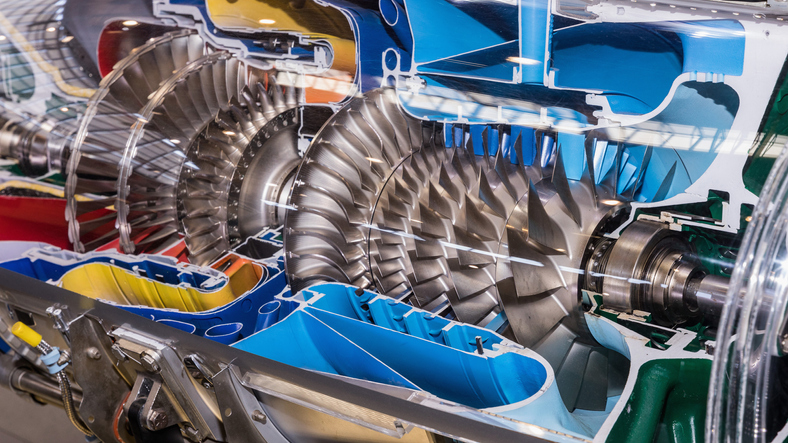

Demystifying the PT6A Engine

The PT6A engine is a marvel of modern engineering, powering a wide array of aircraft with efficiency, reliability, and versatility. But how does this powerhouse work its magic?